Internal guitar case dimensions:

| Length | 1022mm | 40 1/4" |

| Lower Bout | 324mm | 12 3/4" |

| Upper Bout | 279mm | 11 " |

| Body Length | 457mm | 18 " |

| Body Depth | 51mm | 2 " |

| Empty Weight | 4.07kg | 8.97lbs |

Unique "Liteflite" Construction

Case inner cross section

The criteria for the design called for the construction of the very best lightweight cases possible, encompassing the use of the finest modern materials. The result is a range of cases manufactured using a unique composite double moulded construction which gives unparalleled protection for your instrument from a lightweight case with a low/medium retail price range.

The construction consists of a moulded, high impact resistant A.B.S. plastic outer shell, bonded directly to an inner moulding manufactured from a unique blend of 'High Tech' cellular foam. This inner moulding is feather light and, being semi-rigid, is designed to soak up impact shocks from the outside world. The UNIQUE bonding of the inner moulding to the outer shell gives unbeatable, total structural rigidity which is UNMATCHED BY ANY OTHER CASE IN THE WORLD in our price range.

Acrylonitrile Butadeine Styrene, (A.B.S.) due to it's unique balance of properties, produces mouldings which have strength, toughness and rigidity over a wide temperature range. These characteristics make it first choice for applications throughout manufacturing businesses world-wide – from computer housings to motor car bumpers – and of course, Hiscox cases!

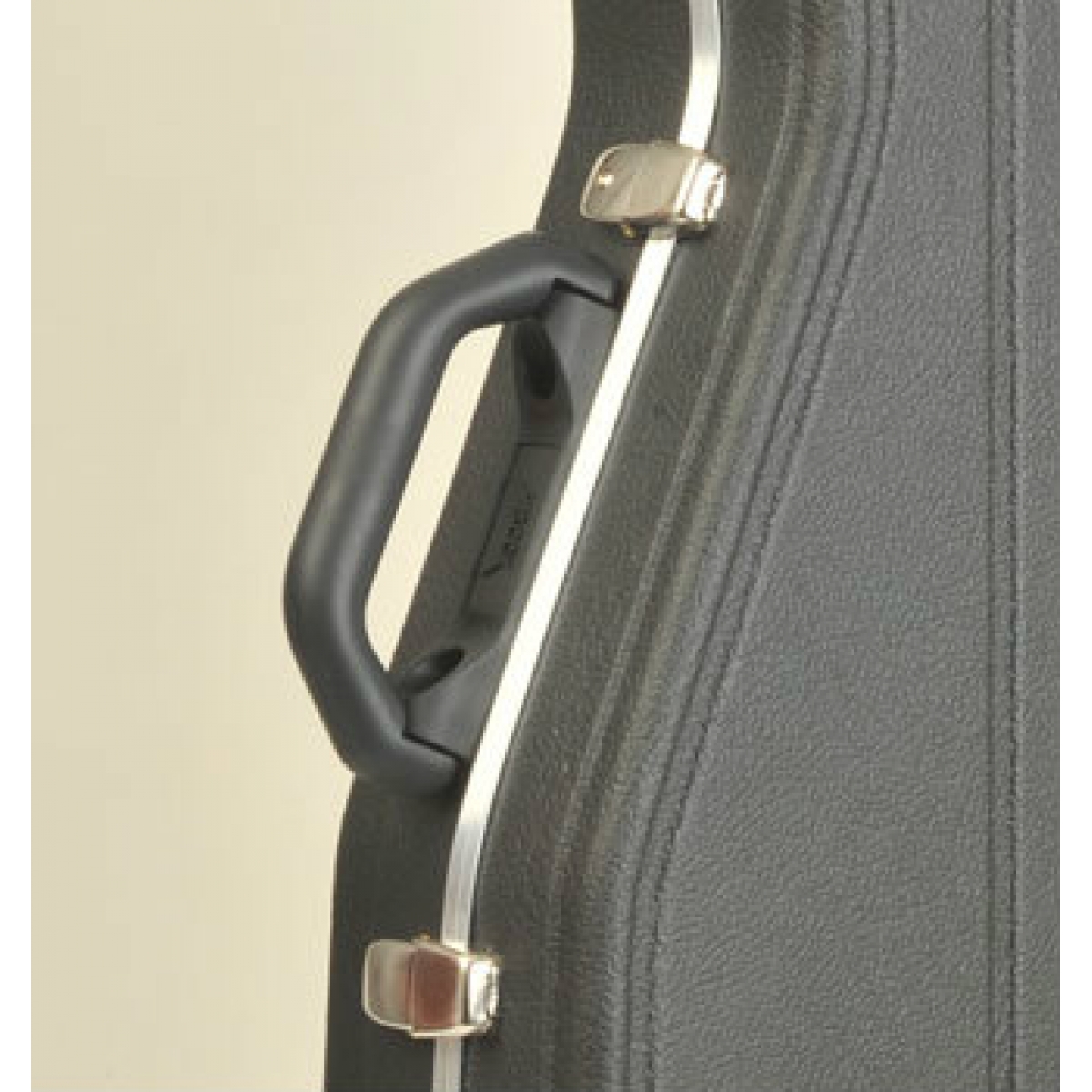

All fixings are riveted through the

hardware into the aluminium valance

The case lining is completed with a crushed velvet type fabric of different grades depending on case type. This is bonded directly onto the shaped foam moulding giving a neatly tailored luxurious feel, perfectly fitted every time. Extra cushioning is provided by upholstered pads in the PRO and Artist ranges which are factory fitted in key areas. These can also be supplied loose in order that the body cavity may be customised to provide a closer fit for a particular instrument.

The aluminium valance is unique to Hiscox Cases. It's design not only increases the rigidity of the case, but ensures a positive location of lid to base when the two halves are closed. Unlike any other case available on the market, the valance extends deep inside the case behind the plastic shell, into which all the hardware (handles, catches, hinges etc.) is riveted. This method of fixing greatly reduces the possibility of fittings working loose. With their incredible structural rigidity, all Hiscox 'Liteflite' cases exhibit enormous crush strength – even our standard case range have has been tested to over 500kg (five fully grown people).

Excellent Thermal Insulation

Thermal insulation test results. Hiscox Liteflite Pro II case versus plywood case and other moulded case with polystyrene inner moulding.

Hot Test

All three cases were at 16°C before being placed in the oven. The oven temperature started at 24°C, rising to 70 °C after one hour. A thermo probe was placed inside the closed cases, and the temperature inside the case was checked at intervals up to one hour.

Time taken to reach 35°C internally

- Plywood case = 20 minutes

- Other moulded case = 27 minutes

- Hiscox Liteflite case = 45 minutes

Cold Test

All three cases were at 16°C internally before being placed in freezer set to -20°C. A thermo probe was placed inside the closed cases, as with the hot test.

Time taken for interior of cases to drop to 0°C

- Plywood case = 14 minutes

- Other moulded case = 25 minutes

- Hiscox Liteflite case = 42 minutes

Conclusion

Both the hot and cold tests clearly show the excellent temperature insulation properties of the Hiscox Liteflite structure.

The Hiscox structure exhibits superior thermal insulation properties when compared to plywood and other moulded cases despite being lighter in weight.

Case weights as tested:

- Plywood case = 4.5kg

- Other moulded case = 4.7kg

- Hiscox Liteflite case = 4.0kg

Why Buy a Hard Case?

Quite simply – PROTECTION! Sadly, this is often a neglected aspect of buying a musical instrument. It doesn't matter how much the instrument cost financially, if it is valuable to you, it is worth protecting.

Gig bags are great for keeping the dust and the kid's sticky fingers off your prized possession, and maybe even the wind and rain, but what happens when you get forced against a lamppost in the street or you're trying to squeeze through a crowded doorway. Knocks, bumps and breakage's suddenly become a very real, and potentially costly danger.

A good quality hard case significantly reduces the risk of instrument damage and may even be limited to the case itself. But there are hard cases and there are hard cases and, as with most things in life, you only get what you pay for. There are many cheap cases available but check the quality, the guarantee (if any) and the after sales support and repair service.